HomeAbout UsBook a RepairRequest a Quote

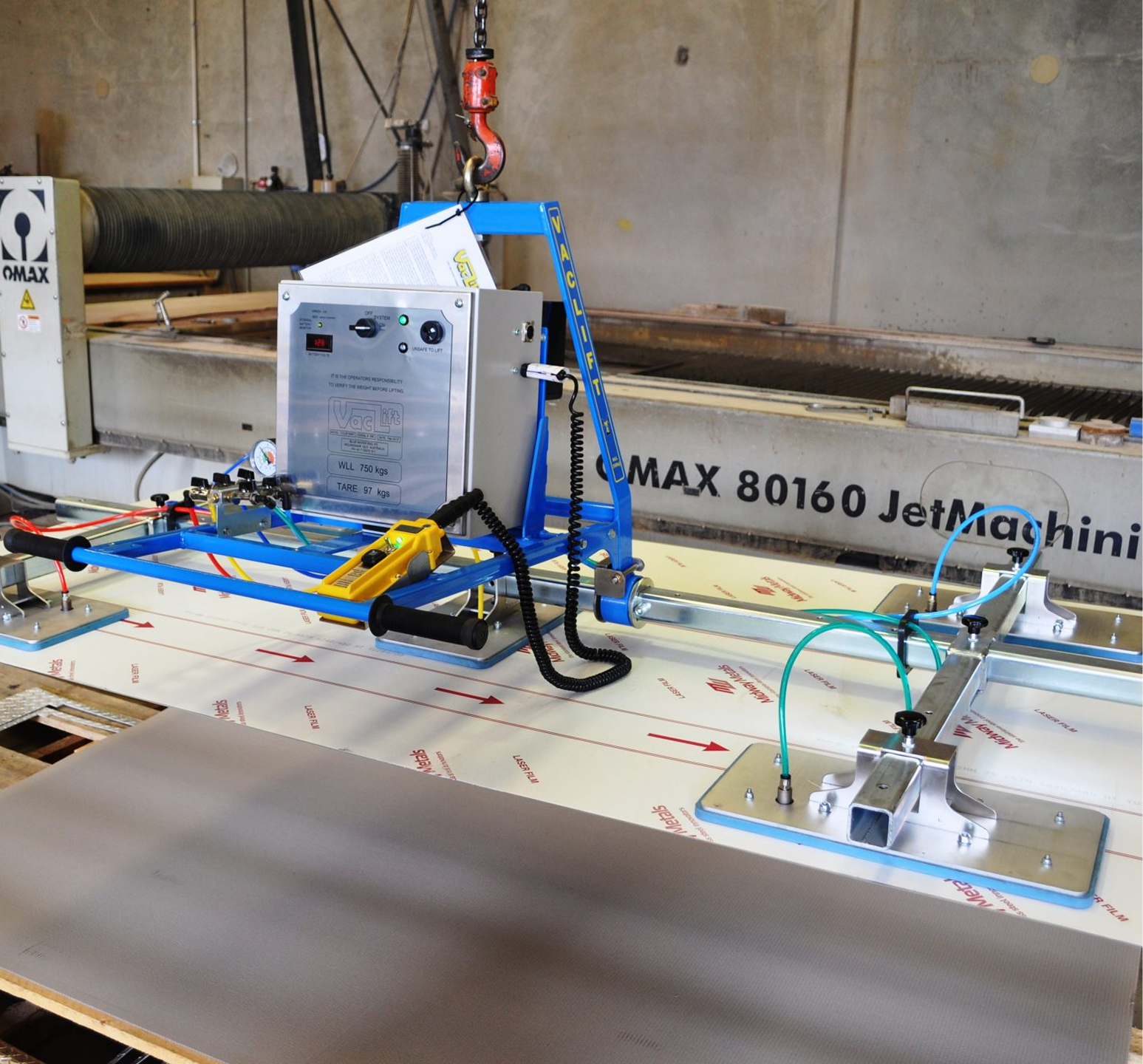

Battery Vaclift Unit

Portable, Versatile, and Strong

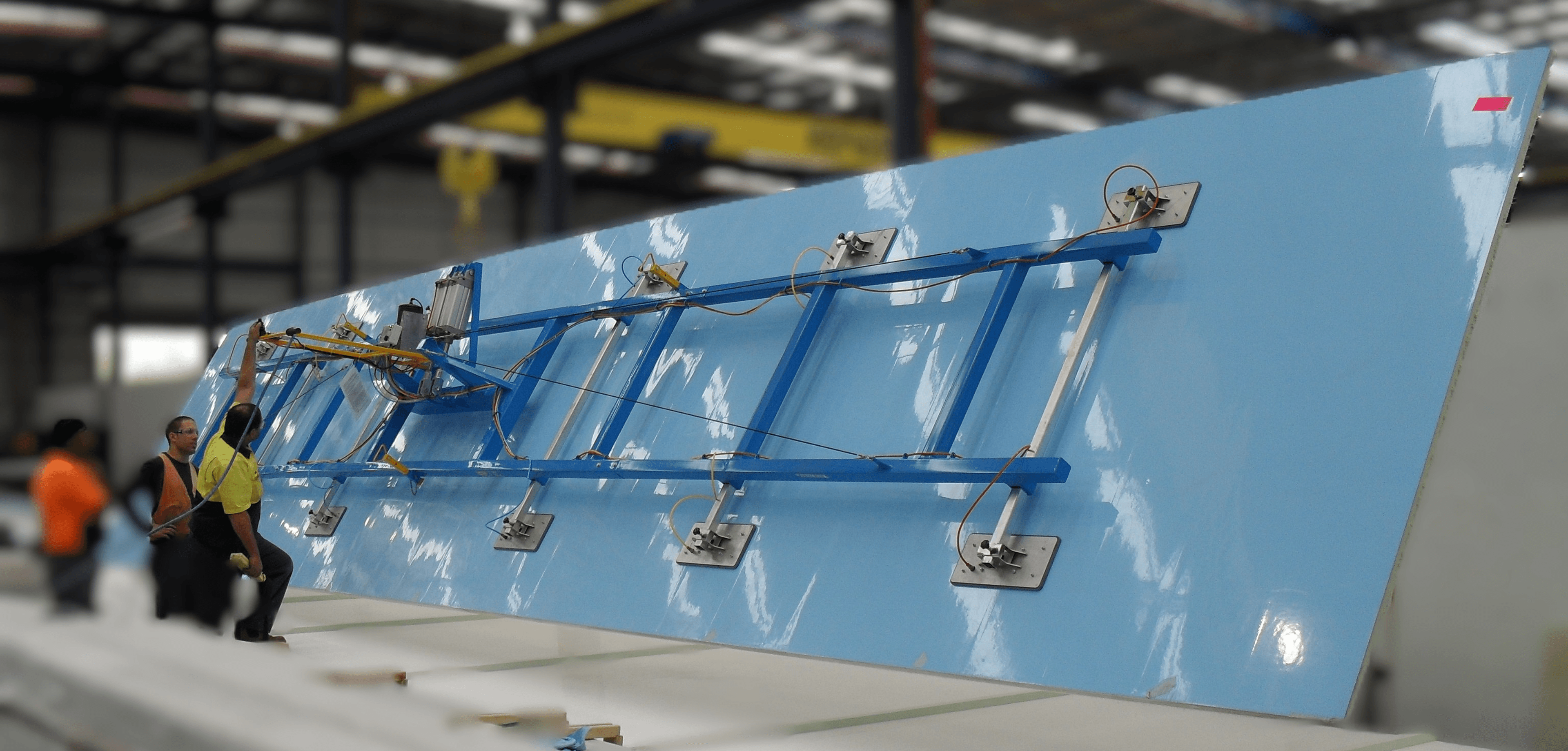

Crane / Jib VacLift (CVL)

Vertical Tilt, Swing & Rotate Capabilities

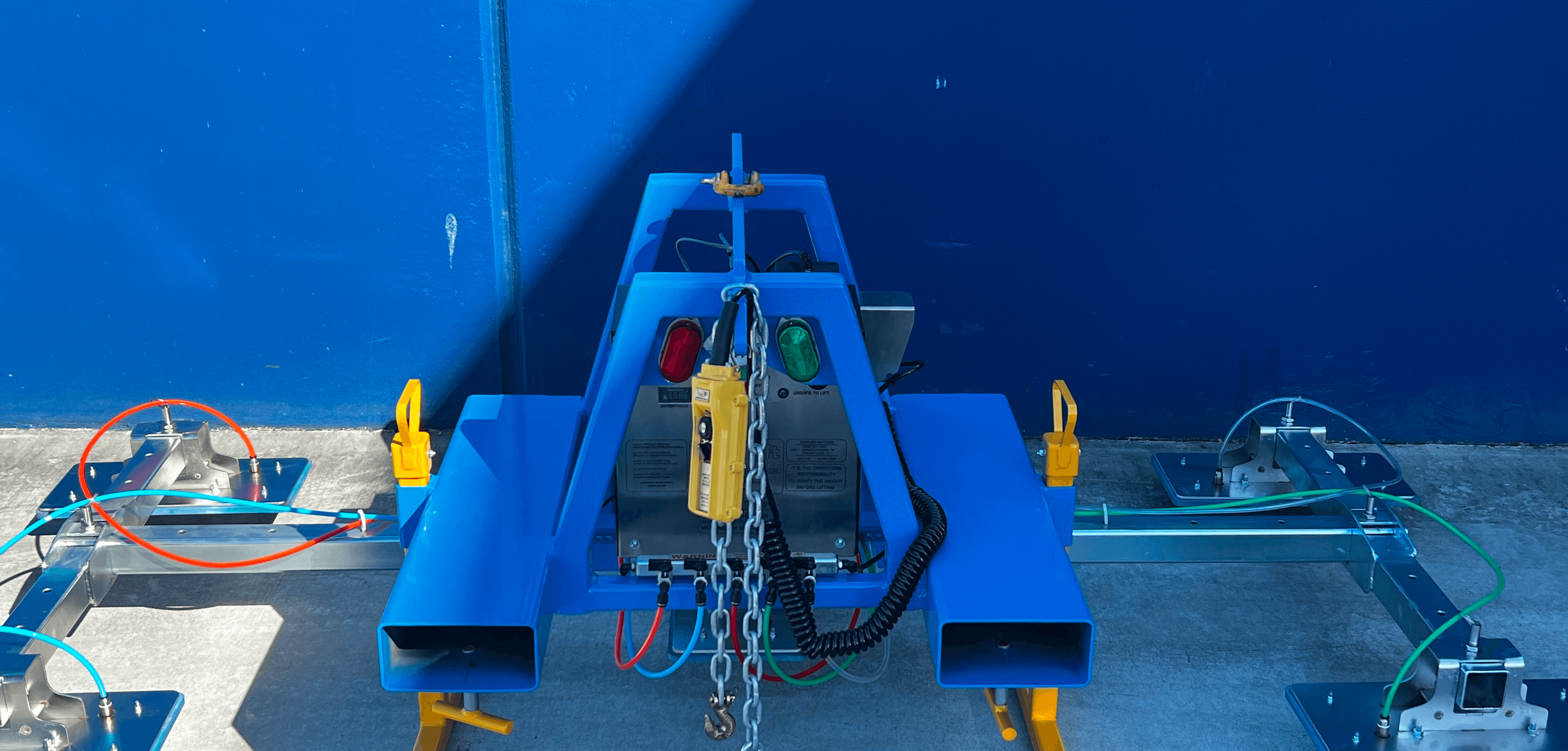

Fork / Crane VacLift (FVL)

Ideal for Large Sheets, Roofing Panels & Onsite Work

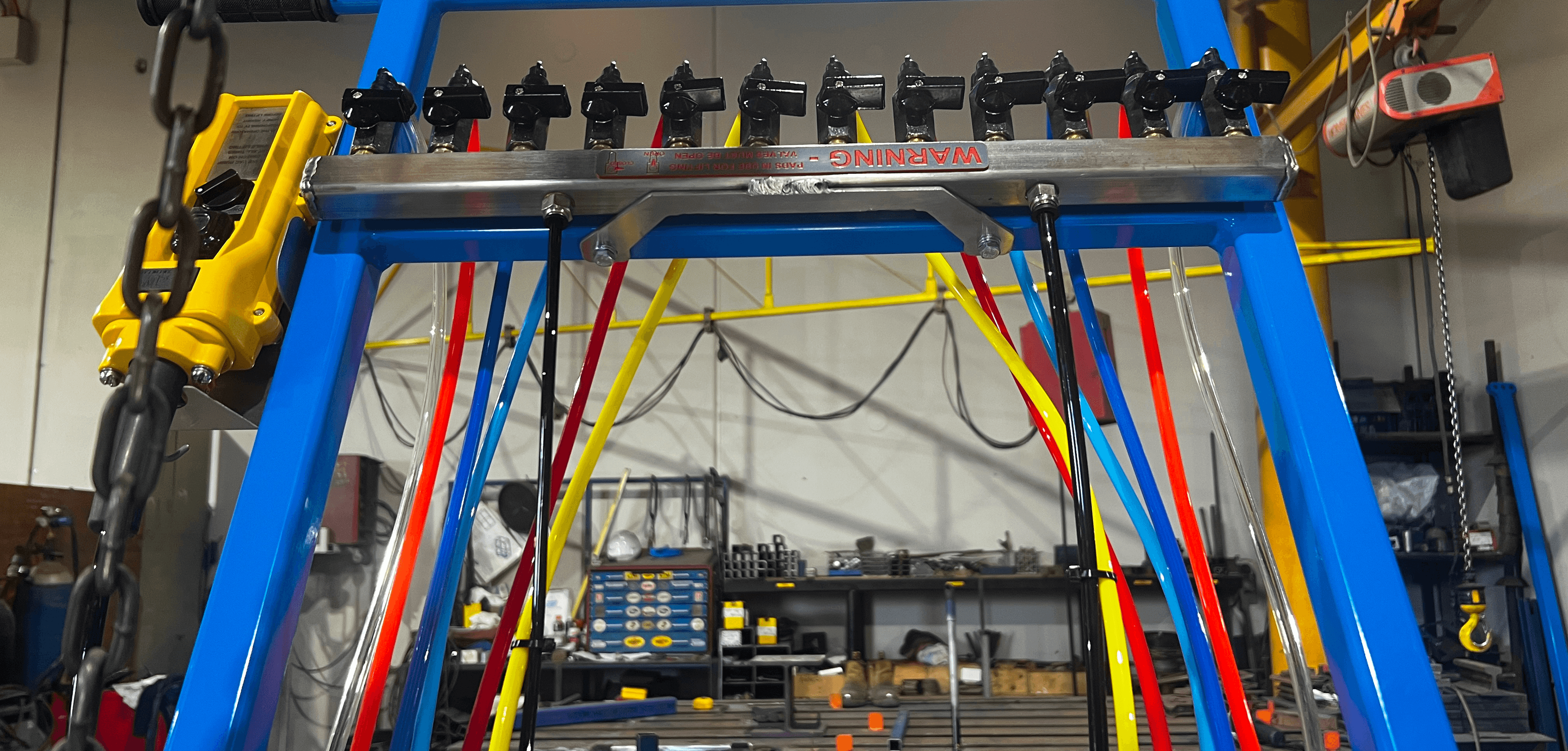

Compressed Air VacLift

Reliable, Spark-Free Operation in Wet Environments

Vaclift for Glass Handling

Precision Lifting for Glass, Stone & Non-Porous Surfaces